Safety optimisation in the crane boom

For our client active in the cement industry, both the walking platform in the crane boom and the shielding of a telescopic conveyor were tackled.

The stairs in the crane boom were removed on both sides and replaced by a continuous sloping walking surface without abrupt height differences and provided with the necessary anti-slip. In addition, the extendable conveyor belt was protected from human contact by means of glass fibre reinforced plastic grids that can be removed very easily for preventive or curative maintenance. The result is a significant improvement in safety in the crane quiver and reduces the risk of personal injury in the event of an incident.

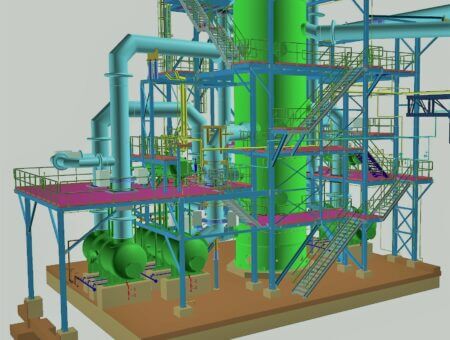

The crane boom was fully mapped internally by 3D scan in order to prepare the design of the new tread and guard in detail in the contractor’s workshop.

The installation of the tread in the crane tube was carried out in 2 phases to keep the downtime of the crane as low as possible.

ContactDescription

At the customer’s request, various technical proposals were worked out that met the specific safety requirements. Based on the proposals, the customer selected a final design.

The final design was described in the technical specifications, which were used as the basis for a competition for different contractors.

After a technical and price evaluation of the different offers, the final contractor was appointed who could be responsible for the execution of this project.

The execution of the works was planned down to the last detail in consultation with production and maintenance in order to limit the downtime of the crane to a strict minimum.

Thorough work preparation was crucial to minimise all risks and guarantee a smooth installation.

Communication was very important to make this project run smoothly and easily.